About the Course

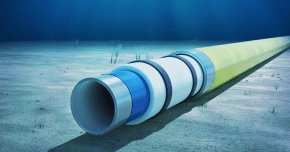

The Construction of Subsea Pipelines course is a detailed four-day programme designed for professionals involved in the offshore oil and gas industry. It focuses on the various techniques, technologies, and practical challenges associated with the construction and installation of subsea pipelines. This comprehensive course covers all critical aspects, including S-lay and J-lay methods, reel-lay techniques, landfall procedures, and pre-commissioning steps, ensuring participants gain a thorough understanding of the entire construction process.

The programme begins with an exploration of S-lay and J-lay methods, detailing their processes, vessel types, and specific applications. Participants will learn about the intricacies of S-lay processes, including the types of vessels used, the sequence of laying operations, and market dynamics. The course also covers insulated lines, lay curve control, and the essential aspects of pipe supply, welding, Non-Destructive Testing (NDT), and External Corrosion Assessment (ECA).

Next, the course delves into J-lay techniques, providing insights into rapid pipe welding, mechanical connectors, and the J-lay sequence from drilling rigs. Participants will explore the design and fabrication of bundles, towhead structures, insulation, and heating systems. The installation of flexibles, including unbonded processes, umbilical cables, and bonded hoses, is also covered. The reel-lay method is thoroughly examined, including its process, market, vessels, and special considerations for offshore pipeline installation.

The course then addresses critical phases in offshore pipeline installation, such as landfalls and tie-ins. Participants will learn about various landfall methods, including pulling ashore into cofferdams, onshore construction sites, and directionally-drilled landfalls. The course covers tie-ins with flanged connections by divers, hyperbaric welding, and diverless tie-ins. Pre-commissioning activities like gauging, flooding, hydrotesting, dewatering, and valve testing are also discussed, alongside Quality, Safety, Health, and Environmental (QSHE) considerations, such as risk assessment and environmental impacts.

Seabed modification, post-lay trenching, and burial techniques are also crucial components of the course. Participants will explore seabed modification methods, including sweeping, rock removal, protection, rock dumping, and the use of concrete mattresses and protective structures. The course covers post-lay trenching and burial techniques, including ploughing, jetting, cutting, cable trenching, trench transitions, and backfilling.

Diving and ROV operations are integral to subsea pipeline construction, and the course provides detailed training on these aspects. Participants will learn about the equipment and procedures involved in diving and ROV operations, ensuring the stability and safety of offshore pipelines.

Throughout the course, practical application of theoretical knowledge is emphasised. Interactive exercises, real-world case studies, and collaborative group sessions enhance the learning experience, allowing participants to apply what they have learned to their professional roles effectively.

By the end of the course, delegates will have a comprehensive understanding of subsea pipeline construction techniques, equipped with the skills to manage and execute complex offshore projects. This training is essential for professionals seeking to advance their expertise in subsea pipeline construction and contribute to the efficiency and safety of offshore operations.

Who's it for

The Construction of Subsea Pipelines course is tailored for professionals involved in the design, installation, and maintenance of subsea pipeline systems. This includes:

-

Project engineers managing subsea pipeline construction projects.

-

Design engineers responsible for creating and validating pipeline construction plans.

-

Installation engineers overseeing the installation and commissioning of subsea pipelines.

-

Maintenance personnel tasked with the upkeep and operational integrity of pipeline systems.

-

Subsea integrity engineers focused on maintaining and enhancing the integrity of subsea pipelines.

-

Technical team leaders and managers leading teams in subsea pipeline operations and project management.

This course is designed to enhance the professional development of individuals dedicated to mastering advanced concepts in subsea pipeline construction.

Learning Objectives

-

Summarise offshore pipeline installation techniques and their applications.

-

Evaluate construction methods for different subsea environments.

-

Implement effective pre-commissioning procedures.

-

Assess and mitigate risks associated with subsea pipeline construction.

-

Understand QSHE considerations and regulatory requirements.

Course Content

-

Day One

S-lay

- What is S-lay?

- S-lay vessel types

- S-lay process

- S-lay market and vessels

- Insulated lines

- Lay curve control

Pipe supply, welding, NDT and ECA

- Line pipe supply and specifications

- Welding procedure

- Welding methods

- NDT

- ECA

-

Day Two

J-lay

- What is J-lay?

- J-lay sequence

- J-lay projects

- J-lay vessels

- J-lay performance

- Rapid pipe welding

- Mechanical connectors

- J-lay from drilling rig

Bundles and towed installation

- What are bundles?

- Bundle design

- Bundle fabrication

- Towhead structures

- Towing methods

- Insulation and heating systems

- Deep-water bundles

- Pros and cons of bundles

- Surface tow

Installation of flexibles

- Unbonded flexibles installation process

- Umbilical cables

- Bonded hoses

Reel-lay

- What is reel-lay?

- Reel-lay process

- Reel-lay market and vessels

- Special considerations

-

Day Three

Landfalls

- Pull ashore into cofferdam

- Pull ashore from onshore construction site

- Directionally-drilled landfalls

Tie-ins

- Flanged connection by diver

- Hyperbaric welding

- Diverless tie-ins

Pre-commissioning

- Gauging and flooding

- Hydrotesting

- Dewatering, air and vacuum drying

- Testing of valves and controls

Quality, safety, health and environment (QSHE)

- Law

- QA

- HSE management

- Risk assessment

- Health

Safety

- Environmental

- Survey

- Survey methods

- Survey operations

-

Day Four

Seabed modification

- Sweeping

- Rock removal

- Protection

- Rock dump

- Concrete mattresses

- Protective structures

- Crossings

Post-lay trenching and burial

- Ploughing

- Jetting

- Cutting

- Cable trenching

- Trench transitions

- Backfilling

Diving and ROV operations

- Diving and equipment

- ROV operations

Learning Outcomes

By the end of the course, delegates will have:

-

A comprehensive understanding of S-lay and J-lay pipeline installation methods.

-

Practical knowledge of reel-lay techniques and their applications.

-

Mastered the pre-commissioning steps necessary for pipeline integrity.

-

Enhanced ability to manage QSHE aspects in offshore construction projects.

-

Developed skills in seabed modification and post-lay trenching techniques.

-

Class Materials

- Case studies that explore real-world subsea engineering challenges and their solutions.

- A comprehensive course manual detailing all essential topics and technical data.

- A collection of references and practical worked examples to deepen understanding and application of the material.

-

Start Dates

Our courses are delivered live online by expert tutors from 9am to 5pm each day, with class sizes capped at 12 participants to ensure personalised attention.

2025 Public Course Dates:

-

6th May to 9th May (09:00-17:00 UK)

-

28th October to 31st October (09:00-17:00 UK)

For other dates, please speak to the team.

-

-

Jeenius

Participants in the Construction of Subsea Pipelines course gain access to Jeenius, a cutting-edge learning platform that offers comprehensive support tools. This platform includes all course notes, recordings of the sessions for later review, and the opportunity for one-on-one support with the tutor. Additionally, Jeenius provides access to the latest insights in subsea engineering, enhancing the learning experience with up-to-date industry knowledge.

-

In-Company Delivery

For in-company delivery options and content customisation to meet your specific needs, please don't hesitate to reach out to us.

-

Fee

£2,495 per person.

Your Tutor

Andy Stevenson

Meng (Hons), CEng, FIMechE

LEAD TUTOR

As a tutor, Andy leverages his extensive industry knowledge in the construction of subsea pipelines course. His teaching approach is deeply rooted in practical application, ensuring that delegates not only understand the theoretical aspects of subsea construction but also how these concepts are applied in real-world scenarios. Andy excels in translating complex engineering processes into accessible and engaging learning experiences. His classes are enriched by his first hand experiences and insights, providing delegates with an in-depth understanding of the challenges and solutions in subsea pipeline construction. Through his guidance, Andy empowers students with the knowledge and skills necessary to excel in the rapidly evolving world of offshore engineering.

Testimonials

"Great training! Pretty elaborate exposure to construction of subsea pipelines. Way to go Jee!"

"Pipe construction and installation is a new thing for most of us, but we were all very impressed with how clear his presentations were and how patient he was. I shall definitely recommend Jee courses in future. Thanks again!"

Similar Courses