About the Course

The Further Design of Subsea Pipelines course is a comprehensive four-day programme designed for professionals seeking to deepen their understanding of advanced subsea pipeline design concepts. This course covers critical topics such as pipe-soil interaction, hydrostatic collapse, corrosion mechanisms, lateral and upheaval buckling, strain-based design, fatigue, and High Integrity Pressure Protection Systems (HIPPS). The curriculum is structured to provide a thorough exploration of these advanced topics, incorporating real-world case studies and practical examples to ensure participants gain hands-on experience and applicable knowledge.

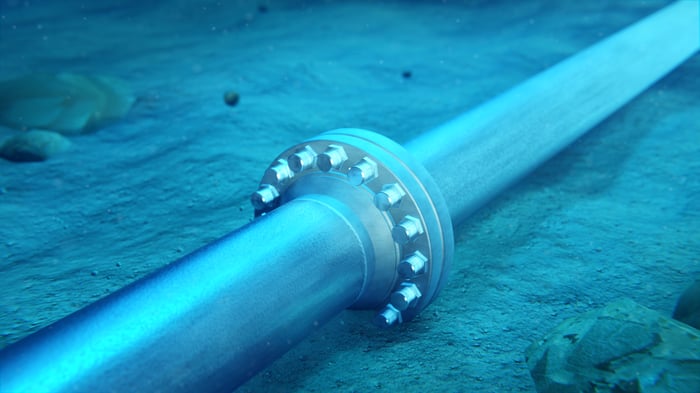

The programme begins with an in-depth look at pipe-soil interaction, where participants will learn about different soil types, pipeline embedment, and methods to resist upheaval. Detailed sessions on hydrostatic collapse will explain the necessity and application of buckle arrestors, supported by practical examples to illustrate the concepts effectively.

Corrosion mechanisms and mitigation strategies form a significant part of the course. Delegates will explore various corrosion control methods, calculate corrosion rates, and review case studies that highlight the practical application of these strategies. This module ensures that participants can design pipelines that are robust and durable against environmental degradation.

The course also delves into the complex phenomena of lateral and upheaval buckling. Participants will learn about virtual anchor spacing, design processes, and how to mitigate these issues through out-of-straightness surveys and practical interventions. A practical example will help solidify understanding of upheaval buckling analysis and mitigation techniques.

Strain-based design principles are thoroughly covered, addressing low, moderate, and high strain requirements in different loading scenarios. The course includes sessions on fatigue, explaining the principles, loadings, and design considerations, supported by worked examples and case studies to provide a comprehensive understanding of how to ensure pipeline integrity under cyclic loading conditions.

Participants will also explore pipeline expansion, walking modes, and anchoring strategies. This module covers the effects of pressure and temperature changes on pipeline behaviour, and how to implement effective prevention and mitigation measures. A detailed case study will illustrate the practical applications of these concepts.

The final part of the course focuses on HIPPS and pipeline protection strategies. Delegates will learn about the configuration, components, and design applications of HIPPS, as well as how to conduct risk and safety analyses. The course will cover various protection methods, including coatings, rock dump, trenching, and protection structures, providing a comprehensive overview of how to safeguard pipelines from potential hazards.

Throughout the course, the practical application of theoretical knowledge is emphasised through interactive exercises and collaborative group sessions. This approach not only enhances the learning experience but also fosters a network of professionals who can share experiences and solutions to common challenges in subsea pipeline design.

By the end of the course, delegates will have a deep understanding of advanced subsea pipeline design concepts, equipped with the skills to address complex challenges and ensure the integrity and reliability of subsea infrastructure.

Who's it for

The Further Design of Subsea Pipelines course is tailored for experienced professionals involved in the design, installation, and maintenance of subsea pipeline systems. This includes:

-

Project engineers managing advanced subsea pipeline projects.

-

Design engineers responsible for creating and validating complex pipeline designs.

-

Installation engineers overseeing the installation and commissioning of advanced subsea pipelines.

-

Maintenance personnel tasked with the upkeep and operational integrity of sophisticated pipeline systems.

-

Subsea integrity engineers focused on maintaining and enhancing the integrity of subsea pipelines.

-

Technical team leaders and managers leading teams in advanced subsea pipeline operations and project management.

This course is designed to enhance the professional development of individuals dedicated to mastering advanced concepts in subsea pipeline design.

Learning Objectives

-

Summarise the design approaches for high-pressure, high-temperature, and high-corrosion environments.

-

Design pipelines for collapse and buckle propagation resistance.

-

Calculate corrosion rates and understand the associated mechanisms and methods.

-

Evaluate different levels of strain and their design requirements.

-

Investigate the causes of fatigue and calculate acceptability.

-

Assess and mitigate pipeline walking.

-

Predict potential hazards and recommend effective pipeline protection methods.

Course Content

-

Day One

Pipe soil interaction

-

Soil types and properties

-

Pipeline embedment

-

Axial pipe-soil interaction

-

Lateral resistance

-

Buried pipeline upheaval resistance

Hydrostatic collapse

-

Need for buckle arrestors

-

Buckle arrestors

-

Worked example

Corrosion

-

Corrosion mechanisms

-

Corrosion control

-

Corrosion rates

-

Case studies

-

-

Day Two

Lateral buckling

-

Virtual anchor spacing

-

Design process

-

Out-of-straightness surveys

-

Buckle mitigation

Upheaval buckling

-

Upheaval buckling mechanism

-

Upheaval buckling analysis

-

Worked example

Strain-based design

-

What is strain-based design?

-

Loading

-

Low strain requirements

-

Moderate strain requirements

-

High strain requirements

-

-

Day Three

Fatigue

-

Principles of fatigue

-

Fatigue loadings

-

Design for fatigue

-

Worked example

-

Case studies

Expansion, walking and anchoring

-

End expansion

-

Pipeline walking

-

Walking modes

-

Pressure effects

-

Walking and lateral buckling

-

Anchoring

-

Other prevention and mitigating measures

-

Case study

-

-

Day Four

HIPPS

-

Configuration and components

-

Design applications

Pipeline protection

-

Hazards

-

Pipeline loads

-

Pipeline load capacity

-

Risk and safety analysis

-

Pipeline coatings

-

Rock dump

-

Trenching for impact protection

-

Protection structures

-

‘Soft’ protection options

-

Learning Outcomes

Upon completion of this course, participants will be able to:

-

A thorough understanding of advanced pipe-soil interaction and pipeline embedment techniques.

-

Mastered the application of buckle arrestors to prevent hydrostatic collapse.

-

Gained practical knowledge in corrosion control and mitigation strategies.

-

Developed skills in lateral and upheaval buckling analysis and mitigation.

-

Enhanced their ability to perform strain-based design and fatigue analysis.

-

Learned effective strategies for pipeline expansion, walking, and anchoring.

-

Acquired expertise in configuring HIPPS and conducting pipeline protection and safety analyses.

-

Class Materials

- Case studies that explore real-world subsea engineering challenges and their solutions.

- A comprehensive course manual detailing all essential topics and technical data.

- Detailed notes from the tutor, Mike Hawkins, offering additional insights and expertise.

- A collection of references and practical worked examples to deepen understanding and application of the material.

-

Start Dates

Our courses are delivered live online by expert tutors from 9am to 5pm each day, with class sizes capped at 12 participants to ensure personalised attention.

2025 Public Course Dates:

-

27th - 30th May (09:00 - 17:00 GMT)

-

11th - 14th November (09:00-17:00 UK)

For other dates, please speak to the team.

-

-

Jeenius

Participants in the Further Design of Subsea Pipelines course gain access to Jeenius, a cutting-edge learning platform that offers comprehensive support tools. This platform includes all course notes, recordings of the sessions for later review, and the opportunity for one-on-one support with the tutor. Additionally, Jeenius provides access to the latest insights in subsea engineering, enhancing the learning experience with up-to-date industry knowledge.

-

In-Company Delivery

For in-company delivery options and content customisation to meet your specific needs, please don't hesitate to reach out to us.

-

Fee

£2,495 per person.

Your Tutor

Mike Hawkins

BTech,CEng, FIMechE

LEAD TUTOR

Testimonials

"Jee delivers the promised topics. The course covered a lot of important topics and I feel more prepared to do my daily tasks at work. It gave me cohesion and the possibility to see the big picture."

"Thanks to this course you gain new insight, shift perspective and gain a greater awareness of the rules, processes and methods for subsea pipeline designing. Highly recommended."

Similar Courses