About the Course

The Offshore Remedial Works course is a comprehensive two-day programme designed for professionals in the offshore oil and gas industry. It focuses on the critical aspects of inspection, investigation, and repair processes for offshore structures. This course combines theoretical and practical learning, including real-world case studies, to equip participants with essential skills for preventing and solving common offshore problems.

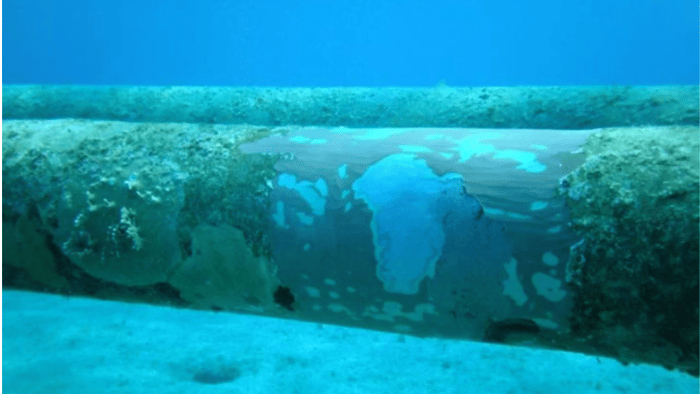

The programme begins with a detailed exploration of inspection and investigation techniques. Participants will learn about common problems encountered offshore, various inspection methods, and analysis techniques through case studies. This foundational knowledge is essential for identifying and understanding the conditions that necessitate remedial actions.

Next, the course delves into preparatory works required before repairs. This includes excavation design, coating removal, and surface preparation. These steps are crucial for ensuring that repair processes are carried out effectively and efficiently. The programme then addresses different repair scenarios, including the use of diving and remotely operated vehicle (ROV) operations. Participants will gain insights into various repair methods, the functionality and capability of different techniques, and the requirements for major repairs and isolation.

The course also covers execution and testing procedures, including the development of procedures, process safety, pre-deployment testing, and post-repair testing. These sessions are designed to ensure that participants can plan and execute repairs safely and effectively, with a strong emphasis on practical execution and real-world application.

A significant portion of the course is dedicated to common remedial works, such as stabilisation options, span and buckle remediation, and the installation of protection measures. This includes retrofitting anodes and other protection systems. A detailed case study on buoyant span provides practical insights into the problem background, assessment, remediation, and lessons learned, offering a comprehensive view of remedial strategies.

Finally, the course explores remediation design, focusing on rock-dump berm design, protection requirements, mattress considerations, and the impact of seabed mobility. Participants will learn how to design effective remediation strategies that address the specific challenges of offshore environments.

Throughout the course, interactive exercises and collaborative group sessions enhance the learning experience, allowing participants to apply theoretical knowledge to practical scenarios. This approach fosters a network of professionals who can share experiences and solutions to common challenges in offshore remedial works.

By the end of the course, delegates will have a comprehensive understanding of offshore remedial work techniques, equipped with the skills to manage and execute complex repair projects. This training is essential for professionals seeking to advance their expertise in offshore operations and contribute to the safety and efficiency of offshore structures.

Who's it for

The Offshore Remedial Works course is tailored for professionals involved in the inspection, maintenance, and repair of offshore structures. This includes:

-

Project engineers managing offshore repair projects.

-

Inspection engineers responsible for planning and conducting inspections.

-

Installation engineers overseeing the execution of repair works.

-

Offshore operations engineers involved in day-to-day management of offshore assets.

-

Technical team leaders and managers leading teams in offshore remedial operations.

This course is designed to enhance the professional development of individuals dedicated to mastering advanced concepts in offshore remedial works.

Learning Objectives

Upon completing this course, delegates will be able to:

-

Summarise offshore inspection and investigation techniques and their applications.

-

Evaluate preparatory works required before offshore repairs.

-

Implement effective repair methods and understand their capabilities.

-

Assess and mitigate risks associated with offshore repair projects.

-

Understand QSHE considerations and regulatory requirements in offshore remedial works.

Course Content

-

Day One

Inspection and investigation techniques

-

Common problems

-

Inspection methods

-

Investigation and analysis

-

Case study

Preparatory works

-

Excavation design and implementation

-

Coating removal

-

Cleaning and surface preparation

Repairs

-

Repair scenarios

-

Diving and ROV considerations

-

Repair methods, functionality and capability

-

Major repairs

-

Isolation requirements

Execution and testing

-

Procedure development and process safety

-

Pre-deployment testing

Setting up and surveying -

Executing

-

Testing and acceptance

-

Case study

-

-

Day Two

Common remedial works

-

Stabilisation options

-

Span and buckle remediation

-

Installation of protection measures

-

Retrofitting of anodes

Buoyant span case study

-

Background to the problem

-

Buoyant span assessment

-

Remedial works

-

Lessons learnt

Remediation design

-

Rockdump berm design

-

Protection requirements

-

Mattress considerations and specification

-

Consideration of seabed mobility

-

Learning Outcomes

Upon completion of this course, participants will be able to:

-

A comprehensive understanding of integrity management systems for flexible pipelines and risers.

-

Practical knowledge of inspection planning and risk-based inspection techniques.

-

Enhanced ability to analyse and mitigate risks in flexible pipeline operations.

-

Developed skills in the repair and maintenance of flexible pipelines and risers.

-

Improved capability to manage the integrity of subsea assets throughout their lifecycle.

These outcomes prepare delegates to effectively address the challenges in the integrity management of flexibles and risers, ensuring they can contribute significantly to their organisations and the industry.

-

Class Materials

- Case studies that explore real-world subsea engineering challenges and their solutions.

- A comprehensive course manual detailing all essential topics and technical data.

- Detailed notes from the tutor, Dem Demetriou, offering additional insights and expertise.

- A collection of references and practical worked examples to deepen understanding and application of the material.

-

Start Dates

Our courses are delivered live online by expert tutors from 9am to 5pm each day, with class sizes capped at 12 participants to ensure personalised attention.

2025 Public Course Dates:

-

27th - 28th May (09:00-17:00 UK)

-

28th -29th October (09:00-17:00 UK)

For other dates, please speak to the team.

-

-

Jeenius

Participants in the Offshore Remedial Works course gain access to Jeenius, a cutting-edge learning platform that offers comprehensive support tools. This platform includes all course notes, recordings of the sessions for later review, and the opportunity for one-on-one support with the tutor. Additionally, Jeenius provides access to the latest insights in subsea engineering, enhancing the learning experience with up-to-date industry knowledge.

-

In-Company Delivery

For in-company delivery options and content customisation to meet your specific needs, please don't hesitate to reach out to us.

-

Fee

£2,495 per person.

Your Tutor

Phil Goby

CEng, MIMechE

LEAD TUTOR

Testimonials

“Dense in information but made congestible by many samples and videos”

“It actually opened up new windows of opportunity to me”

Similar Courses